ECT has been providing conformal coating services in the US and Canada for over 25 years and recently added Parylene coatings as a new value-added service. Liquid-free parylene coatings provide the ultimate level of protection for electronics that will encounter extreme environmental conditions such as extended exposure to moisture or harsh chemicals.

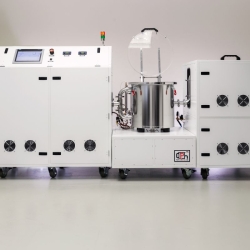

Parylene coatings are applied in a unique batch process at room temperature using a chemical vapor deposition (CVD) process. Ahead of going into the CVD equipment, boards are prepared by applying light-curable maskants, adhesive dots, or tapes to prevent the film from entering critical keep-out areas. Based on the application requirements, dimer C or N is selected. A precise amount of dimer powder is inserted under a vacuum and heated until vaporized. The vapor gas particles then enter the room temperature deposition chamber where the gas settles and encapsulates the entirety of the PCB with absolute precision. The result is consistent, ultra-thin coating between 0.25 and 0.75 microns thick that offers perfect uniform coverage with marginal weight added to the PCB.

Parylene is a highly reliable coating often used in the aerospace, defense, spacecraft, and automotive markets. Both Parylene C and Parylene N are clear in appearance, making them ideal for optical applications. The process is completed at an ITAR and ISO 9001-2015 registered facility, operating in accordance with industry standards IPC-A-610G and J-STD001G.