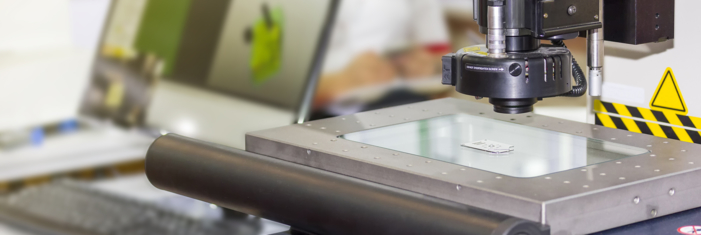

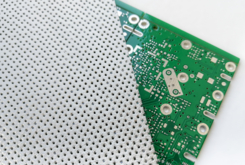

EMI/RFI Shielding

Electronic Coating Technologies has been working with leading EMI/RFI material shielding manufacturers for over 20 years. We will find the best electronic shielding for your application and work with you through the entire application process.